Brake Pads

Annexed Information

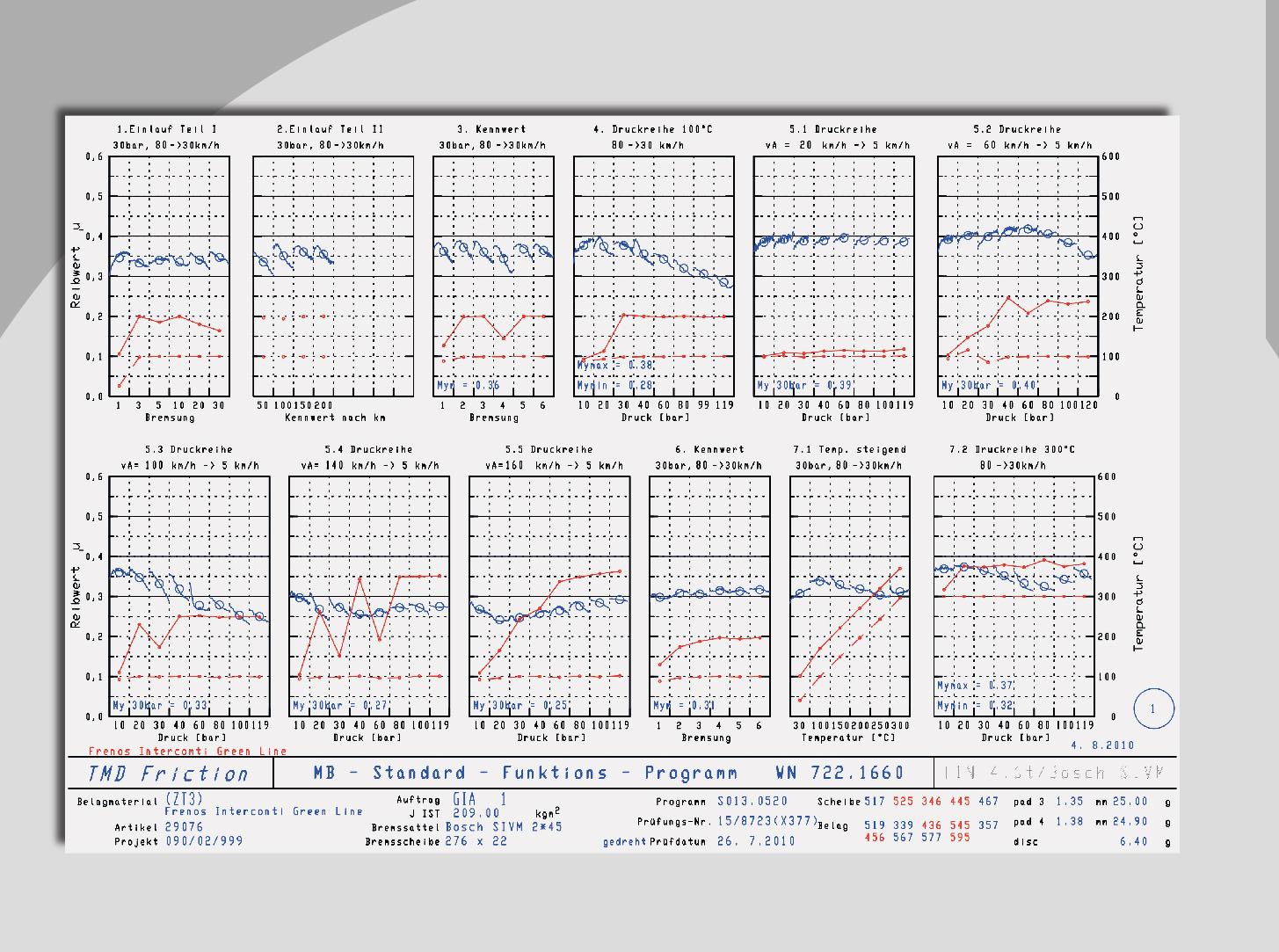

ECR-90 TMD test in Germany

Hitch Plates, For Hitch Plate

"The solution advanced patented and registered"

With the hitch plate for the hitch plate, a new age started for transport. It is a piece that is added to the hitch completing it, acting as an “interface” between itself and the semi-trailer. In comparison, it predominates all that is known for the same function. Its use gives competitive advantages over the rest. In fact, for qualities, it has long been obligatory in countries like Germany.

How does it work?

The hitch plate is the link that links the truck to the semi-trailer. This joint is assembled with two ferrous materials: on the one side the plate with the bolt on the semi-trailer, and on the other side the head of the plate or cast iron coupling plate. Both of them are subjected to rotational movements (turns) and displacements (in starts and stops), and all this under great load and force. This generates friction (wear) and bumps between the parts, effects that can be smoothed out with this hook plate between the parts.

What is used until today and how does it work?

Until today it is common to use grease, to prevent the two parts from coming into direct contact with each other and protect them from wear and gears. But this solution is very limited and cannot avoid multiple drawbacks:

-

• Grease is a material that flows and therefore runs off and lasts a short time instead. It involves a high cost.

-

• This forces frequent decoupling movements, greasing and re-coupling.

-

• Dirt and dirt sticks to the road.

-

• Dries easily and then stops effectively protecting the plate from wear by friction and over demands the bolt and mechanisms.

-

• Grease dirties and ruins everything that splashes, for example hoses, etc.

-

• As the grease drips and dries, the behavior of the semi-trailer on the road varies, with the dangers that this implies.

What are the advantages of using the Hitch Plate?

The hitch plate consists of a sheet that is fixed on the plate. Due to its qualities it offers a definitive solution:

-

• German Technology, Argentine Industry.

-

• High mechanical resistance.

-

• Very resistant to wear and abrasion (dirt, dust)

-

• Made of a material developed to have very low friction (self-lubricating).

-

• It is resistant to hydrocarbons.

-

• Resists high temperatures (up to 250 ° C).

-

• It is economical, safe, ecological and offers permanent comfort.

-

• No grease on the surface, saving time, money and reducing risks.

-

• Smooth and permanent silent sliding in any circumstance.

-

• Greater ride stability (controlled friction).

-

• Better manoeverability and braking.

-

• Continuity with behavior.

-

• Cleaning in the plate area, towards the rear and in the rest of the semi-trailer.

-

• Hoses and connections are not contaminated.

-

• Simplicity and cleanliness in the unhooking and hooking maneuvers.

-

• It is antistatic, electrical insulating and fire retardant: it does not take static charges with friction. For this reason it is mandatory in fuel transport trucks.

-

• The plate does not undergo deformations or stretching due to temperature, contamination by grease or excess weight.

-

• Makes the life of the chainring head eternal and increases the useful life of the bolt and its locking mechanisms.

-

• The hitch plate has a useful life of more than one year.

-

• Its chemical and physical composition is patented.

WITH REGISTERED AND PATENTED GERMAN LICENS