L-L Friction coefficient 0,12μ-0,18μ

L Friction coefficient 0,15μ-0,22μ

K Friction coefficient 0,24μ-0,30μ

The test evaluates the behavior of friction material subjected to conditions of use by simulating a passenger car in a vehicle under two general conditions:

A- With maximum load / minimum load

B- Normal speed / maximum speed

1- OBSERVATION OF THE SAMPLE

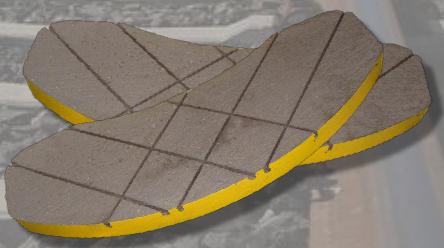

The first comment to highlight arises from the observation of the geometry of the piece delivered for testing. The delivered sample has two remarkable design features that are novel compared to what is known in the market and very important that significantly improve the performance of the material, particularly at the beginning, i.e. since it is installed.

Indeed, due to its geometry, it ensures that the shoe starts its work fully resting on the tread of the wheel and, secondly, it does so by ensuring support (at least) at two contact points, which is twice the surface than any other shoe. This is a great improvement over what is known and favorably affects the wheelhouse (system in which the shoes are mounted) and the performance of the brake from the beginning of it.

2- PERFORMANCE

GMC GERMANY 320x80 level K material presented exceeds the limits of the test, it means, that within the parameters of speed, pressure and temperature to which it was exposed in the routine, the behavior is totally stable, and within the pre-established parameters.

At the end of the routine, outside the test protocol, a run at 140 km / h was included and even in this condition, the performance remained within the established parameters.